High-Quality Plastic Molding Injection Companies for Large-Scale Projects

Plastic molding injection companies that succeed at large-scale manufacturing share common characteristics that transcend geography, yet their development has been profoundly shaped by environmental and economic factors specific to their locations.

To understand why certain manufacturers excel at producing millions of identical components whilst others struggle with consistency, we must examine the interplay between technology, geography, labour systems, and institutional frameworks. The story of plastic molding injection companies reveals patterns familiar from other industries: success depends not merely on equipment but on how societies organise knowledge, manage resources, and adapt to constraints.

The Geography of Manufacturing Excellence

Consider two manufacturers, one located in a region with abundant cheap labour, the other in a land-scarce nation with high wages. Logic suggests the low-cost producer would dominate large-scale projects through price advantage. Yet reality proves more complex. The high-wage manufacturer often secures contracts for demanding applications, whilst the low-cost producer handles simpler work.

This apparent paradox resolves when we examine what large-scale projects actually require. Volume alone does not define these undertakings. A large-scale project might involve producing 10 million medical device components annually, each requiring dimensional accuracy within 0.05 millimetres, complete traceability, and validated processes. Another might need 50 million simple housings with looser tolerances and minimal documentation.

These different requirements favour different manufacturing systems. Plastic molding injection companies evolved distinct strategies based on local conditions:

High-Wage Regions

Invested heavily in automation, quality systems, and technical expertise to justify premium pricing through superior capability

Low-Wage Regions

Leveraged labour advantages for high-volume, lower-complexity production where manual operations remain cost-effective

Resource-Rich Areas

Benefited from proximity to petrochemical feedstocks that supply plastic resins

Technology Hubs

Attracted skilled engineers and maintained close links with clients in advanced industries

Neither strategy is inherently superior. Each represents adaptation to local circumstances.

Singapore as a Case Study

Singapore illuminates how geographical constraints shape industrial development. The nation possesses no natural resources, limited land, tropical heat that increases cooling costs, and labour costs rivalling Western Europe. These factors should preclude manufacturing success, yet Singapore hosts world-class plastic molding injection companies serving demanding large-scale projects.

How did this occur? The answer lies in deliberate choices made over decades. Unable to compete on cost, Singapore manufacturers focused on capabilities that justified premium pricing. They invested in climate-controlled facilities, precision equipment, and quality certifications. They recruited engineers and trained technicians. They built relationships with multinational corporations seeking reliable suppliers for critical components.

“We recognised early that Singapore’s future in manufacturing lay not in producing the most parts but in producing the most difficult parts,” explained a manufacturing director whose facility supplies the aerospace industry. “Large-scale projects in high-value sectors became our specialty.”

This strategic choice created a self-reinforcing cycle. Success in demanding applications attracted more sophisticated clients. These clients brought technical challenges that developed manufacturer capabilities further. Reputation for reliability enabled premium pricing that funded continued investment.

The Elements of Large-Scale Capability

What distinguishes plastic molding injection companies capable of handling demanding large-scale projects? Analysis reveals consistent patterns:

Process Stability

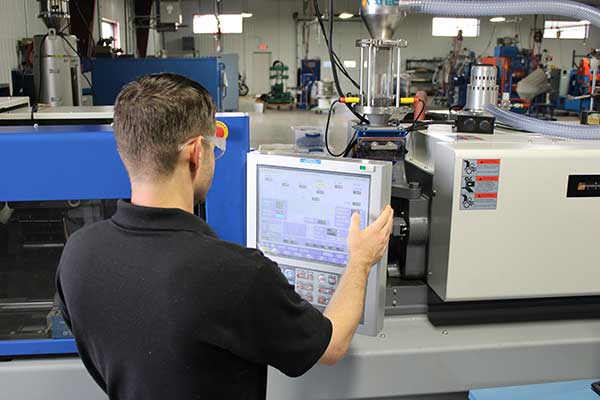

Ability to produce identical parts across millions of cycles through rigorous parameter control and preventive maintenance

Quality Infrastructure

Statistical process control, automated inspection systems, and comprehensive documentation protocols

Material Management

Systems ensuring correct resin grades, proper storage conditions, and lot traceability across production runs

Automation Integration

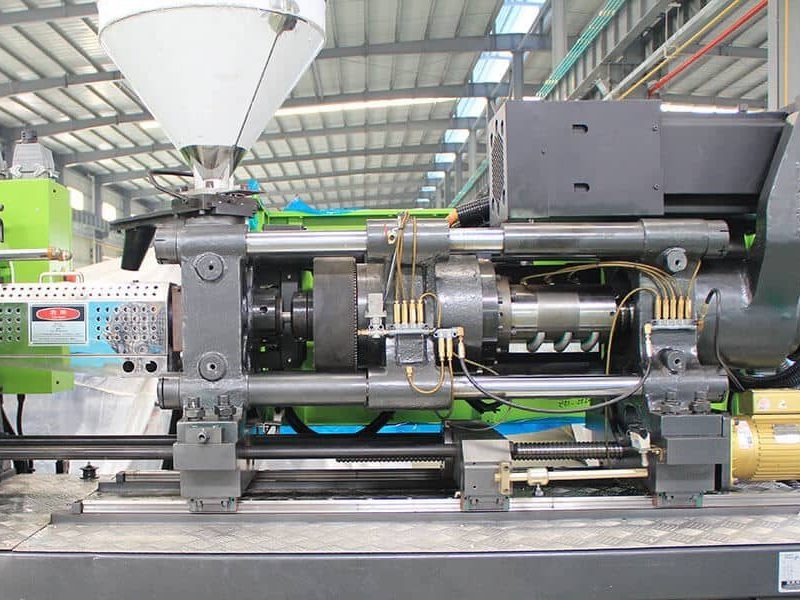

Robotic part handling, automated packaging, and integrated data collection reduce variation from human factors

Backup Capacity

Redundant equipment and contingency plans maintain supply continuity when machines require maintenance

Technical Support

Engineering teams capable of troubleshooting problems and optimising processes without halting production

These capabilities require sustained investment over years. They cannot be improvised in response to individual opportunities.

The Role of Institutions

Beyond physical capabilities lie institutional factors. Successful large-scale manufacturing depends on systems that preserve knowledge, maintain standards, and ensure accountability. Consider quality management systems like ISO 9001. These frameworks document processes, define responsibilities, and create audit trails. They transform individual expertise into institutional memory that survives personnel changes.

Singapore’s plastic molding injection companies benefit from national institutions supporting manufacturing excellence. Government agencies provide technical training, quality certification support, and R&D grants. Industry associations facilitate knowledge sharing. Universities conduct relevant research. These supporting institutions reduce individual company burdens whilst elevating overall sector capability.

Environmental Pressures and Adaptation

Large-scale production generates substantial waste and consumes significant energy. Environmental regulations increasingly constrain how plastic molding injection companies operate. Singapore’s limited land area and high population density make environmental compliance particularly stringent.

These pressures drive innovation. Manufacturers adopt closed-loop cooling systems, optimise cycle times to reduce energy consumption, and implement recycling programmes for production waste. “Environmental constraints we initially viewed as burdens became competitive advantages,” noted a sustainability manager. “Clients increasingly prefer suppliers demonstrating environmental responsibility.”

Comparative Advantage in the Modern Era

The future of plastic molding injection companies will be shaped by automation, material innovation, and changing economics. As automation reduces labour cost advantages, manufacturing may partially relocate from low-wage to high-skill regions. As environmental regulations tighten, manufacturers with established compliance systems gain advantage. As supply chains shorten, proximity to customers matters more.

These trends favour manufacturers who invested in capability over capacity, in systems over scale, in quality over quantity. The patterns we observe across successful plastic molding injection companies reveal an enduring truth: sustained excellence in large-scale manufacturing emerges not from single factors but from how technology, geography, institutions, and human capital combine to create adaptive, resilient production systems.